2020. 2. 29. 06:44ㆍ카테고리 없음

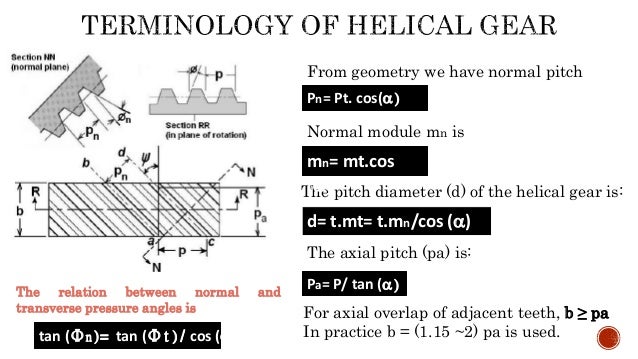

Figure 3 The calculated local tooth friction coefficient above the zone of contact (left); the average toothfriction coefficient computed from this; further the gear meshing efficiency above the meshingposition (right) derived from latter.Figure 3 represents that the local coefficient of the toothfriction is changing strong along a single contact line (thesame color belongs to the same meshing position of theworm). It assumes its maximum value at the middle of thetooth where the sum velocity is nearly zero and therefore theboundary lubrication dominates. The average coefficient ofthe tooth friction μtf is also changing strongly depending onthe meshing position of the worm φ1. The curve of the gearmeshing efficiency ηmesh follows the change in the average coefficientof the tooth friction with the reverse trend. It can becalculated by using Reference 9:γ m is the lead angle of the worm and α0 stands for the pressureangle. In the knowledge of the gear meshing efficiencythe input torque T1 of the gear pair can be calculated.

In thenext step, based on the technical mechanic, the bearing reaction forces can be determined. By worm gear drives by bothshafts generally adjusted bearing arrangements were used.The additional pre-stress load of the bearing is computed accordingto (Ref. 10).Bearing losses. Knowing the radial and the axial bearingforces and the rotational speed of the shaft the power losstorque by each bearing can be estimated according to thefour source friction model of the SKF company (Ref. Thisdetermines the total friction moment in a bearing Ml,bear as asum of the rolling frictional moment Mrr, the sliding frictionalmoment Msl, the frictional moment of seals Mseal and the frictionalmoment of drag losses M drag:The details of their calculation are described (Ref. 10); thismethod was used by all four bearings of the gears to determinethe bearing power loss.Oil churning power losses.

At the mechanical engineeringdepartment of ECAM, a physically grounded calculation procedurewas developed to determine the churning power lossof a pinion, which immerged in an oil sump (Ref. A similarmethod by worm gear drives is unknown; therefore thementioned calculation is also used in this paper to estimatethe drag torques M l,chur:Where ρoil is the oil density, n the rotational speed of thepinion, A the wetted surface area of the pinion, dm the pitchdiameter of the pinion and Cm the dimensionless drag torquecoefficient, which can be calculated as follows:Here h means the submerged depth of the pinion, V0 theoil volume, Fr the Froude and Re the Reynolds number. Bothequations are given in the convention used with SI units.Shaft seals power losses. To determine the frictional losstorque of the seals Ml, seal, the following simple equation accordingto Ref. 12 was used:Where dshaft is the diameter of the shaft, bcontact is the contactwidth of the sealing, μ is the coefficient of the friction in thesealing contact and pa is the average contact pressure in thesealing contact. At this point the use of the SI units becomesnecessary.Energy balance of the worm gear unit.

In the knowledgeof every loss component calculated with the presented methods,the efficiency of the worm gear drives can be determined.This calculation is based on the energy balance of theworm gear unit. It expresses that the sum of the input power,the output power and the power losses is zero (compare Figure1). Based on this principle of energy conservation, the efficiencyof the worm gear unit can be calculated as follows:Here the power of the worm Pworm is increased with thepower losses of the input shaft; this sum corresponds withthe input power of the gearbox.

The power of the worm wheelPwheel is reduced with the power losses of the output shaft; thissum is the output power of the gearbox. Both the power of theworm and the power of the wheel were calculated during thetribological simulation of the worm gear drives. Figure 4 Changing of the input and output torques (left); and changing of the efficiency during the iteration (right).Influence of the power losses on the power losses.

The developedtribological simulation of worm gear drives can onlydetermine the tooth friction power losses of the gearbox. Theother power losses, such as the bearings, oil churnings andseals power losses reduce also the output power. Thereforea higher input power than used at the beginning of the tribologicalcalculation is needed to cover the necessary outputpower of the gearbox.

Worm Gear Design Pdf

It means that an iterative calculationmust be used to determine the real operational condition ofthe worm gear unit. Figure 4 shows the changing of the input and output torqueand the changing of theefficiency during thisiteration process. Figure 5 Flow chart of the calculation ofthe gearbox efficiency.Summary of the described calculation procedure. At thispoint a short overview about the developed simulation methodwill be given to determine the efficiency of worm geardrives. The calculation process is illustrated in Figure 5. In thefirst step of the analyses the local tooth friction coefficientsof the worm gear drive were calculated according to (sectionTooth friction power losses). Afterwards, from the local toothfriction coefficients the average tooth friction coefficient wasdetermined, which belongs to the current meshing position.With this knowledge the gear meshing forces and the bearingreaction forces are calculated based on the static equilibriumequations.

With the mentioned method in (sections Bearinglosses; Oil churning power losses; andShaft seals power losses), the additionalpower losses such as bearings, oilchurnings and seals power losses canbe also estimated. These power lossesmodify the input and output torqueof the gearboxes; therefore a new tribologicalcalculation is necessary. Ifthe accuracy of the iteration process isacceptable, the calculation procedurecan be stopped and the solutions canbe put out.Comparison of the Measurement and theSimulationTo validate the developed calculation method, a test benchwas built at the laboratory of MEGT to study the efficiency ofworm gear drives. During the experiment the input and outputtorques and speeds were detected by different operationalconditions. Figure 6 shows the comparison of the efficiencycalculated from the measured values and the simulated averageefficiency of the abovementioned ZK-type gearbox by theload T2 = 430 Nm, and by the sump temperature ϑs = 60° C. Thesimulated curve of the efficiency concurs very well with themeasured values, so the developed simulation technique can be used as a reliable calculation method to determine theefficiency of worm gear drives. Figure 6 Comparison of the measured and simulated efficiency ofthe analyzed gearbox.Analysis of Power LossesThe presented, physically grounded calculation method todetermine the efficiency of worm gearboxes has a singularadvantage compared to conventional empirical equations.While the latter differentiate only between the load-dependentand no-load dependent power losses, the presentedcalculation method separates also between the power losssources.

This enables engineers to not only estimate totalpower loss but also to better understand every power losssource. Thus it is possible to optimize the gearboxes and reductionof losses. Figure 7 Power loss components of the worm gear drive abovethe meshing position.Figure 7 shows the course of all four power loss sourcesduring one rotation of the worm by the load T2 = 430 Nm, andby the input rotational speed n1=1,500 1/min. Depending onthe meshing position, the tooth friction power loss changesstrongly similar to the changing of the tooth friction coefficientin Figure 3.

Its average value is ca. Three times higherthan the second largest power loss — the sum of the fourbearings’ power losses. This is also three times higher in theinvestigated operational point than the oil churning losses.The smallest share has the sum of the three shafts’ sealpower losses. For further analysis of the power sources thepower losses were divided into two groups, depending uponthe location of their generation.

Figure 8 shows the powerlosses by the input (left) and by the output shaft (right). Italso shows that the power losses by the output shaft can beignored compared with losses of the input shaft. The noload-dependent character of the oil churning and the shaftseals power loss should also be easily recognizable (Fig.

8).The high value of the bearing power losses can be explainedwith the high axial force component of the bearing reactionforce and with the high rotational speed of the worm. In theinvestigated case the worm submerged fully in the sump;therefore the churning loss was accordingly high, whereasthe wheel teeth were slightly immersed in the oil sump.